So a week of wagon work, let’s get straight into it.

Monday and after a quick going over by Tim with a wire wheel, Mark applied black to the north side of the Mackerel.

Over in Railworld, Matt and Tim continued with the Conflat prep.

Tim again with the wire wheel.

Whilst Matt continued removing the rotten steel and rivets from the chain pockets.

Tuesday and with the final rivets removed, Matt completed some final prep whilst Tim replaced a few life expired split pins.

Then it was on to some painting. Tim and Mark applying underframe black to the……………….underframe, with Matt first applying red oxide primer, followed by Bauxite. Unfortunately it was not possible to complete the painting as the heavens opened.

Wednesday and the painting continued on the Conflat with Tim, Colin and Matt in attendance.

This sees the Bauxite and the Black completed as far as we can, until the replacement chain pocket skins arrive.

Next attention turned to Palvan B778810 a stalled project from a few years ago that really needs to be completed. Now joined by Jason, the body was keyed and loose paint removed.

A rotten side sheet was also removed, with Jason and Tim cutting and drilling a replacement.

This was then Primed and Undercoated

A rotten door was also removed.

With the final task of the day being to apply undercoat to the north body side.

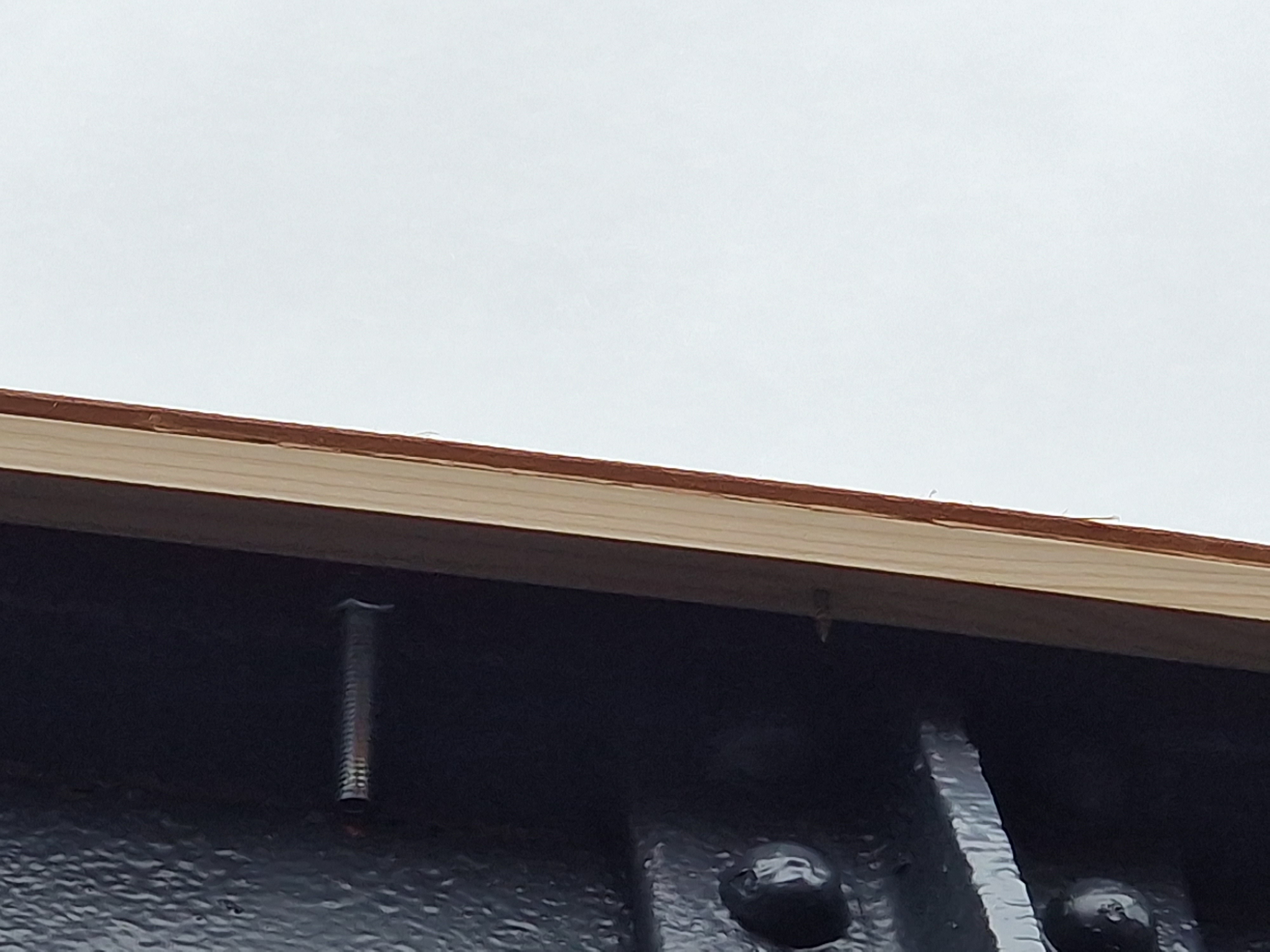

Thursday, and it’s time for some roof action.

Tim and Matt doing the honours, 8’x4’ sheet in each corner drilled and bolted.

Followed by two 8’ support sheets screwed across the width of the roof either side of the van centre, this was then topped with trimmed 4’ sections of ply

Further support pieces were then screwed along the centre line of the roof and again topped off with 3 trimmed pieces of ply.

This resulted in a very smart ply roof, requiring a sheet.

And if that was not enough, the new side sheet was fitted as the light faded on another day.

So on to the final day of our work week, Friday, with Tim and Matt on site.

1”x1/2” wood strips were screwed to either side of the new roof ply and the all excess bolts, screws and ply lengths were trimmed.

A suitable lorry side curtain was selected from stores and the furniture and strapping removed.

Trim panels were also manufactured for the lower portion of the side sheets. These are to strengthen the ply sheets which have deteriorated a little over the years the vehicle has been idle, although a full reskinning would be preferable with the rest of the ply in very good shape, this is a cost saving measure, with only the worst sheet replaced as described above. The plates were drilled and primed.

Unfortunately no images of the roof sheet going on as Tim and Matt just got on with it. The process was to roll the sheet up, lay it on to the roof. Then the west roof hoop was bolted into position clamping the sheet at that end.

It was then rolled out, 3 rail chairs roped to the end to provide tension, whist the second hoop is fitted.

The sides are then stapled to the previously fitted wood strips and the excess sheet trimmed.

Our PVC primer of choice was then applied and then the camera came out.

The trim plates as well as the door retaining latches were fitted and primed.

With the final task for the week being the application of bitumastic black to the roof.

This means the Palvan now has a roof again, a new door is required as well as repairs to another, then a further undercoat and topcoat. The Conflat requires a floor after its chain pocket sheets.

Three vehicles significantly progressed, with a few outstanding tasks this should see them back in traffic.

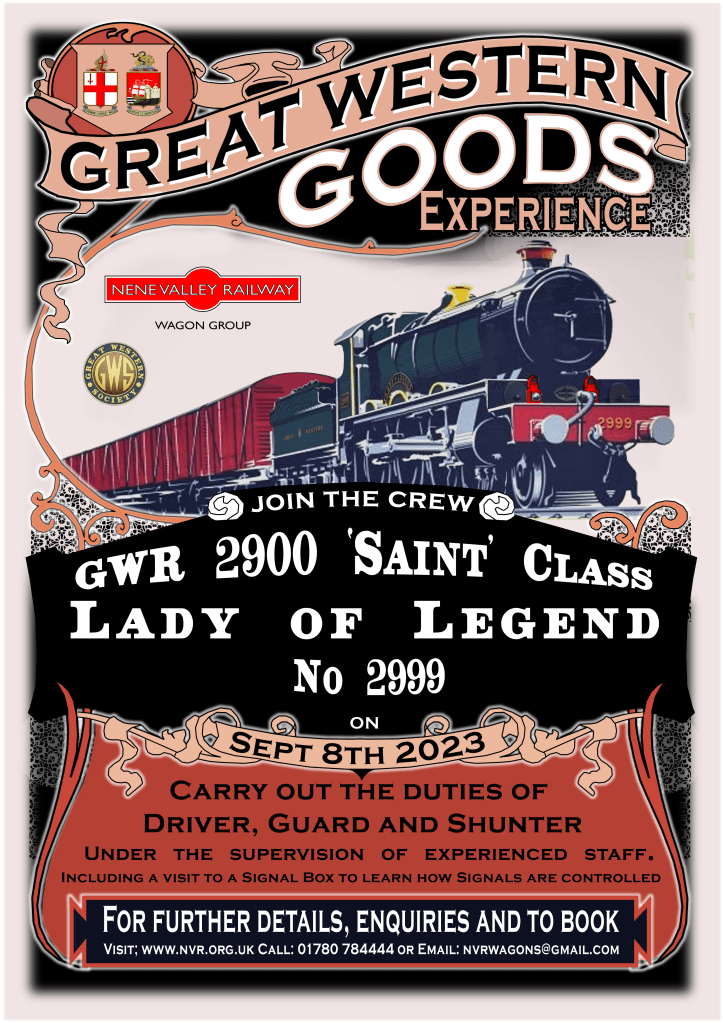

Again a reminder there are still places on out Saint Goods Experience, supporting these events allows us to progress work and return more vehicles to working condition lengthening the freight making the experiences even more challenging.

Please check out our events page for details