Whilst a great deal of mineral traffic in the past would have been conveyed by conventional open or covered wagons, fleets of hopper wagons gradually became more common during the early BR period to help speed the loading and discharge of materials, especially for coal operations where it could be easily loaded at collieries and equally discharged at its destination.

The hopper wagon wasn’t a new introduction for BR. The hopper had long been part of the railway scene, though usually for dedicated freight flows with examples including the famous Tunstead-Northwich ICI workings which used dedicated bogie wagons. There were also 20T hoppers built by the London North Eastern Railway for coal traffic, 20T coke wagons built by the London Midland and Scottish Railway and more.

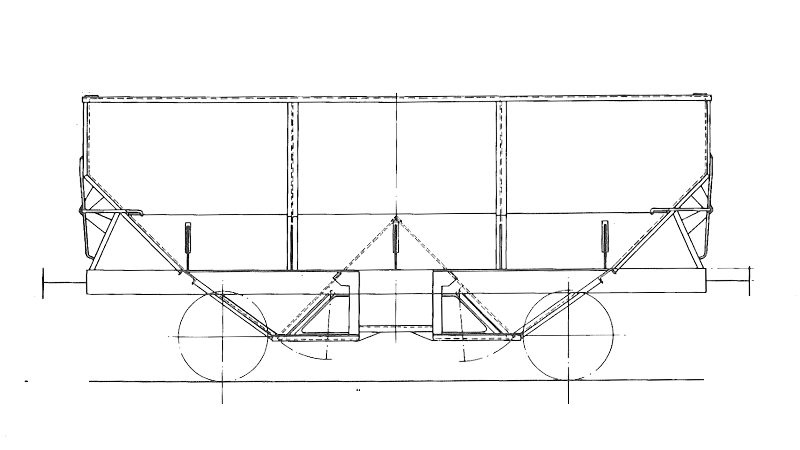

As the requirement for bulk trains grew during the British Railways era so did the range of hoppers in service including more 20T coal hoppers such as ours, a larger capacity 24.5ton hopper, dedicated cement hoppers and vehicles dedicated to stone and iron ore traffic was also developed – the most impressive of the latter being the 56T wagons for the Tyne Dock-Consett trains which featured air-operated hopper doors.

It was during the late 1960s that BR really showed the potential of hopper wagons when it began developing the HAA wagons for Merry-Go-Round trains. This aimed to provide a more efficient, dedicated service between colliery and power station. At the colliery, empty wagons would slowly move through the loading area, before heading for the power station. Each of the main MGR-served power stations would feature a loop line with automatic discharge facilities, which in turn enabled the empty train to return to the colliery without the need for shunting or locomotive run rounds. As part of the emptying procedure, the coal hopper wagons would move at very low speed through the discharge bays from where the coal would be automatically released and then transferred by conveyor belt for storage, until it was required.

As with coal, aggregates, cement, china clay, coke, fly ash, grain, minerals, railway ballast, sugar and more could be loaded and discharged using hopper wagons and by adopting similar procedures, albeit often with more manual intervention. Hopper wagons offered the flexibility for conventional loading/unloading methods too. Whilst many trains ran in bulk formations, some operations such as domestic coal or cement could also appear in mixed freight or pick-up goods services, depending on demand. To accommodate differing payloads both open and covered hoppers were developed.